Products

Related Posts

What is

GA5061VF

?

FEATURES

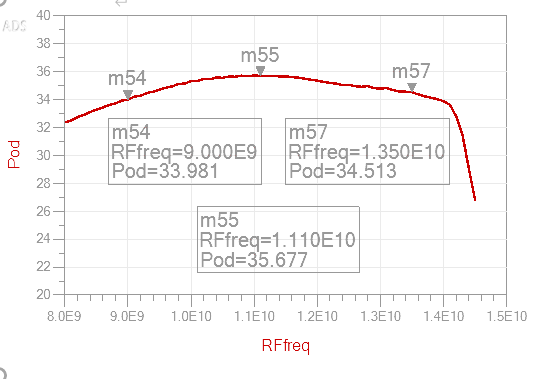

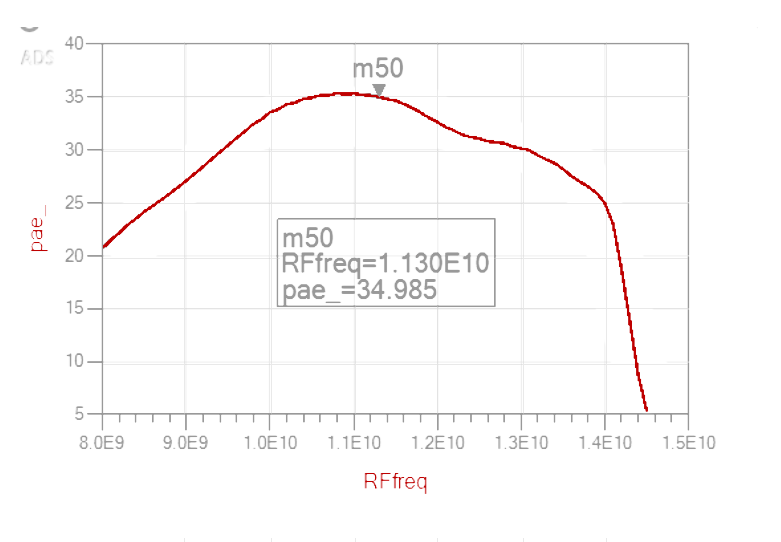

・High Output Power: Pout=34.0dBm (MAX.)

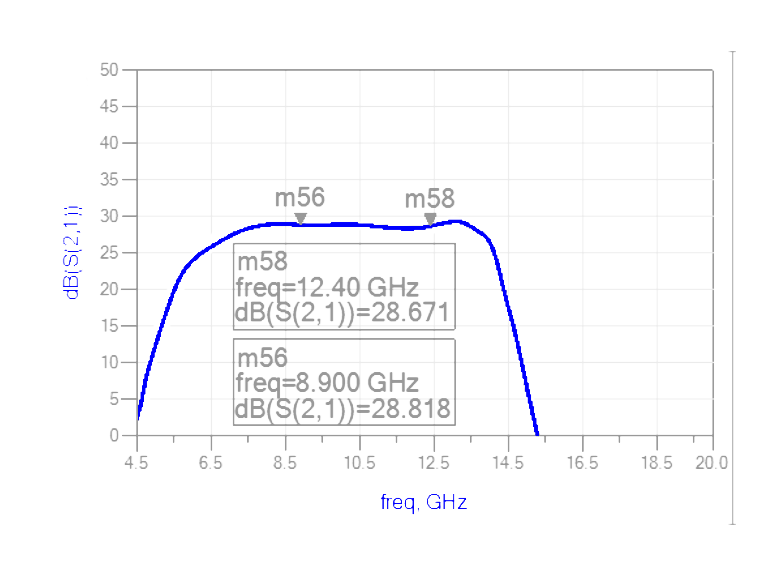

・High Linear Gain: GL=27.0dB (typ.)

・Broad Band: 9.5~13.5GHz

・Impedance Matched Zin/Zout=50Ω

・Small Hermetic Metal-Ceramic Package(VF)

DESCRIPTION

The GA 5061VF is a MMIC amplifier that contains a three-stage amplifier,

internally matched, for standard communications band in the9.5 to13.5GHz

frequency range.

div[class^="e_richText"] .table table.buyao td {border:none !important;}Category:

ABSOLUTE MAXIMUM RATING

|

Item

|

Symbol

|

Condition

|

Rating

|

Unit

|

|

Drain-Source Voltage

|

VDD

|

10

|

V

|

|

|

Gate-Source Voltage

|

VGG

|

-7

|

V

|

|

|

Input Power

|

Pin

|

26

|

dBm

|

|

|

Channel Temperature

|

Tch

|

+175

|

℃ | |

|

Storage Temperature

|

Tstg

|

55~125

|

℃ |

RECOMMENDED OPERATING CONDITION

|

Item

|

Symbo

|

Condition

|

Rating

|

Unit

|

|

Drain-Source Voltage

|

VDD

|

6

|

V

|

|

|

Gate-Source Voltage

|

VGG

|

-5

|

V

|

|

|

Input Power

|

Pin

|

≤12

|

dBm

|

|

|

Operating Case Temperature

|

TC

|

-40~+85

|

℃ |

ELECTRICAL CHARACTERISTICS (Case Temperature TC =25oC)

|

Item

|

Symbol

|

test Condition

|

Limits

|

Unit

|

||

|

Min.

|

Typ.

|

Max.

|

||||

|

Frequency Range

|

f

|

VDD=6V

VGG=-5V

Zs=Zl=50ohm

*1:f=9.5~11.7GHz

*2:f=11.7~13.3GHz

*3:f=10MHz ,

2-Tone Test,

Pout=19dBm

S.C.L.

~ 199 V

|

9.5

|

-

|

13.5 |

GHz

|

|

Output Power at 1dB G.C.P

|

P1dB

|

31*1

29*2

|

33*1

31*2

|

-

-

|

dBm

|

|

|

Power Gain at 1dB G.C.P.

|

G1dB

|

24*1

22*2

|

26*1

24*2

|

-

-

|

dB

|

|

|

Power-added Efficiency at 1dB G.C.P

|

add

|

-

-

|

21*1

15*2

|

-

-

|

%

|

|

|

Third Order Intermodulation*

|

IM3

|

-42*3

|

-45*3

|

-

|

dBc

|

|

|

Drain Current at 1dB G.C.P

|

IDD

|

-

-

|

1700*1

1500*2

|

2400*1

2400*2

|

mA

mA

|

|

|

Gate Current

|

IGG

|

-

|

25

|

-

|

mA

|

|

|

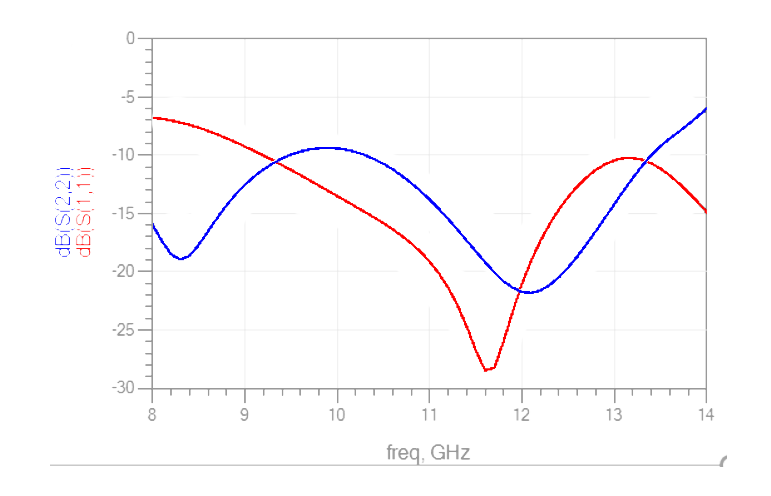

Input Return Loss (at Pin=-20dBm)

|

RLin

|

-

|

-8

|

-

|

dB

|

|

|

Output Return Loss (at Pin=-20dBm

|

RLout

|

-

|

-8

|

-

|

dB

|

|

| ESD |

Class 0

|

|||||

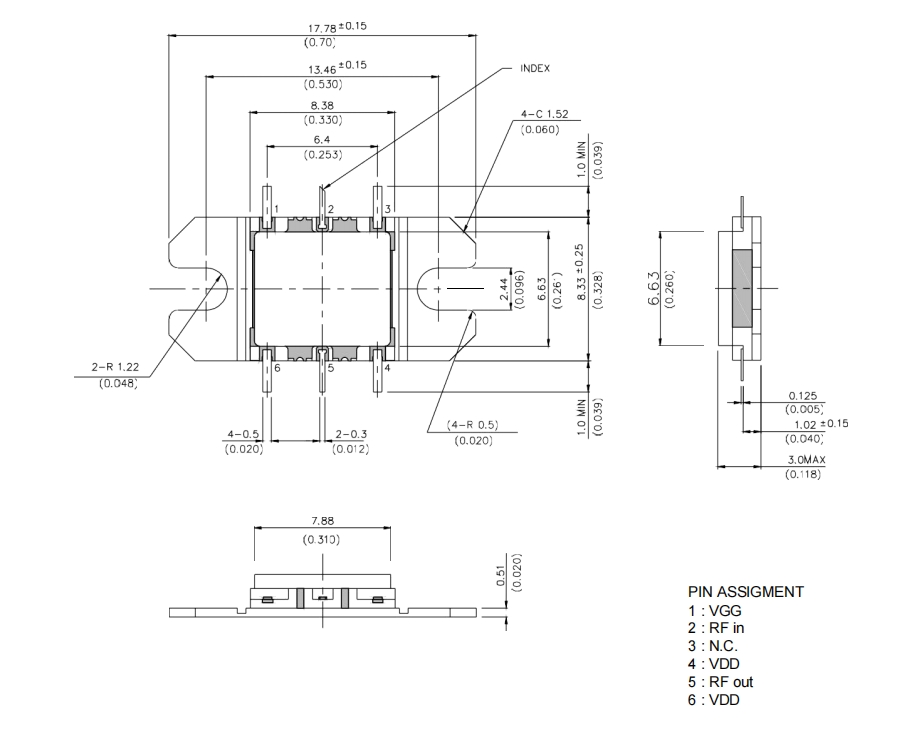

Package Out Line

■Mounting Instructions for VF Package

1.Screw Mounting

(1)The flange of package may be attached using screws. Torque conditions are shown in table 1.

Table 1. Recommended and Maximum Torque for Screw Mounting

|

Package

|

Recommended screw

|

Recommended Torque

|

Maximum Torque

|

|

VF

|

M2.0

|

10 N-cm (0.9 lb-in)

|

15 N-cm (1.3 lb-in)

|

(2)First, tighten the screws with a torque driver set to 5 N-cm.

(3)The surface finish of the heat sink should be better than 0.8 m, and the surface flatness must be better than 10 m.

(4)Silicon based heat sink compounds should not be used for thermal conductive grease. They cause poor grounding of the source flange, contamination and long term degradation of thermal resistance between the FET package and heat sink.

2.Solder Mounting

(1)Recommended solder are Tin-Lead solder (63Sn/37Pb), Lead-Free solder (Sn-3.0Ag-0.5Cu)*1 or equivalent.

(2)For soldering, Tin-Lead solder (63Sn/37Pb) or Lead-Free solder (Sn-3.0Ag-0.5Cu)*1 shall be used. (*1: The figure displays with weight %. A predominantly tin-rich alloy with 3.0% silver and 0.5% copper.)

(3)Recommended Flux is Rosin type with chlorine content: 0.2% or less and a low halogen content. After soldering, the flux residue should be removed by appropriate cleaning methods.

(4)The recommended soldering conditions are as follows: Partial heating method (soldering iron, spot laser/air) Product terminal temperature: 260 deg-C, max. 10 s./terminalor 400 deg-C, 。max. 3 s./terminal.

Previous

Next

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!